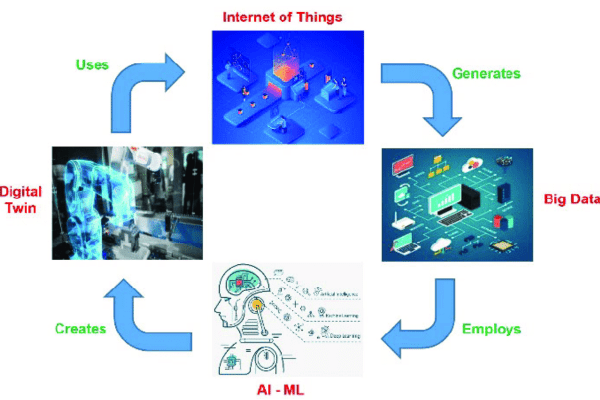

The Digital Twins concept that necessitated building a virtual replica of real assets, wait, no, of processes, or systems has become one of the most adopted technologies in different industrial sectors. The technology indeed allows for real-time surveillance, simulation, and optimization of operations. Although Digital Twins are not something new, their growth is prominently facilitated by the convergence of IoT, AI, and Big Data. According to the Consegic Business Intelligence report, Digital Twin Market size is estimated to reach over USD 142.78 Billion by 2031 from a value of USD 13.21 Billion in 2023 and is projected to grow by USD 17.55 Billion in 2024, growing at a CAGR of 34.7% from 2024 to 2031. The mentioned drivers are fundamentally revamping digital model applications in sectors, completely altering work, and unlocking new ways of technology development and product′s efficiency.

IoT: The Foundation for Real-Time Data

IoT is an essential enabler for the Digital Twin technology. A network of interconnected sensors, devices, and machines allows real-time data collection from physical assets. This flow of data is vital to the process of creating a virtual model that will closely resemble the current state of an asset or a system.

Using IoT, Digital Twins can observe asset efficiency, weather patterns, and operational effectiveness in real-time. This real-time insight is very beneficial, especially in sectors like production, energy, and healthcare, where even small operations matter financially or in safety terms. The persistent input of data to the Digital Twin through IoT helps in forecasting equipment malfunctions, maximizing asset productivity, and the utilization of new maintenance strategies, thereby cutting downtime and costs in operations.

AI: Enabling Predictive and Prescriptive Analytics

The capabilities of Digital Twins are enhanced thanks to Artificial Intelligence which in turn achieves fault detection through predictive and prescriptive analytics. IoT provides real-time data while AI algorithms interpret this data to predict future states, catch errors, and advise corrective measures. The potential that machine learning has is vast, and it could be used to recognize trends in large datasets that are difficult to understand manually, thus, Digital Twin can forecast failures or drawbacks before they occur.

For example, in a manufacturing facility, AI technology can examine the history of machine performance to determine when a component might break down. This action allows a preventive approach, leading to less downtime. Furthermore, AI-fueled Digital Twins can also run various hypothetical “what-if” cases, thus, helping companies in optimal operation in case of different circumstances. Normally, in a populated area, such as cities, the AI challenges of Digital Twin are illustrated by the capacity to model the real-time traffic movement or energy consumption, and sometimes even simulate an emergency response, while at the same time using the gathered data for a better planning and resource allocation.

Big Data: Fueling Comprehensive Simulations The incorporation of Big Data is very important when it comes to making digital twins more accurate and even more useful. Big Data analytics is the driving factor behind the ability of Digital Twins to process large quantities of structured and unstructured data coming from IoT devices and other sources. Through the use of vast datasets, Digital Twins can now offer a bird’s eye view of any asset’s or system’s performance across a span of time, giving an account of the conditions projected and the variables involved. In industries such as aerospace and automotive, the capital equipment performance is a function of many parameters. Big Data integration results in error-free simulation models. Engineers can evaluate engine performance under the different speed, load, and temperature issues they face, picking up the needed data for the simulation from the actual world. This is not only effective in design and manufacturing but also in the safety and reliability of the products.