In today’s rapidly evolving industrial and environmental monitoring landscape, pH sensors play a critical role in ensuring process efficiency, safety, and compliance. These sensors are used to measure the acidity or alkalinity of a solution and are vital across industries such as water treatment, agriculture, food and beverage, pharmaceuticals, and chemical processing. As global awareness around water quality and environmental sustainability increases, so does the importance of reliable pH monitoring technologies.

With a predicted compound annual growth rate (CAGR) of 7.2%, the size of the global pH sensor market is expected to increase from US$1.3 billion in 2025 to US$2.2 billion by 2032. The Persistence Market Research research states that the growing need for accurate and trustworthy pH monitoring across a range of industries is propelling the industry’s notable expansion.

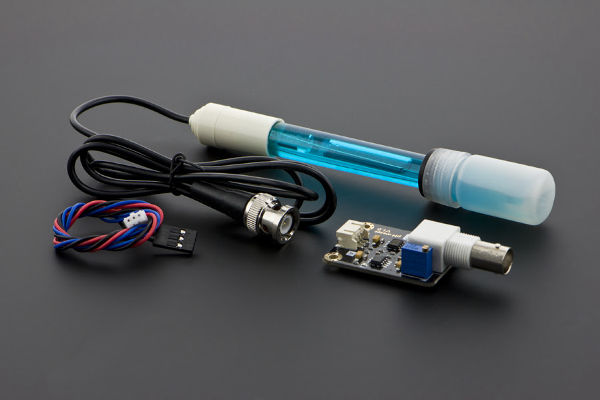

What is a pH Sensor?

A pH sensor is an analytical device used to measure the hydrogen ion activity in solutions, reflecting its acidity or alkalinity. The pH scale ranges from 0 to 14, with 7 considered neutral. Values below 7 indicate acidity, and values above 7 signify alkalinity.

Modern pH sensors typically consist of three main components:

- Measuring Electrode – Detects the hydrogen ion activity.

- Reference Electrode – Provides a stable reference voltage.

- Temperature Sensor – Compensates for temperature-related variations in readings.

There are different types of pH sensors, including glass electrodes, ISFET (Ion Sensitive Field Effect Transistor) sensors, and solid-state sensors. The choice depends on the specific application requirements, such as measurement accuracy, robustness, and maintenance frequency.

Applications of pH Sensors Across Industries

1. Water and Wastewater Treatment: In municipal and industrial water treatment plants, pH sensors are critical for monitoring and controlling the chemical dosing process. Accurate pH measurement ensures that water meets regulatory standards before being discharged or distributed.

2. Food and Beverage Industry: The taste, safety, and shelf life of products in this sector are closely linked to pH levels. From brewing beer to producing dairy products, pH sensors help maintain quality and consistency during production.

3. Pharmaceutical Manufacturing: In the pharmaceutical industry, precise pH control is essential for chemical synthesis and ensuring drug stability. Regulatory guidelines like GMP (Good Manufacturing Practices) demand accurate pH monitoring at every stage of drug production.

4. Agriculture and Soil Monitorin: Soil pH affects nutrient availability and microbial activity. pH sensors help farmers optimize crop yields by providing real-time data on soil conditions.

5. Chemical and Petrochemical Industry: Here, pH sensors help prevent equipment corrosion, optimize chemical reactions, and maintain safety standards.

Technological Advancements in pH Sensing

As industrial processes become more complex, the demand for robust and accurate pH sensors has surged. Innovations in sensor design and materials have led to the development of next-generation pH sensors with improved performance, durability, and connectivity features.

1. Smart pH Sensors

The integration of IoT (Internet of Things) technology has given rise to smart pH sensors that offer remote monitoring, real-time alerts, and predictive maintenance. These sensors can be integrated into SCADA (Supervisory Control and Data Acquisition) systems for seamless automation.

2. ISFET Technology

Ion Sensitive Field Effect Transistor (ISFET) sensors are solid-state alternatives to traditional glass electrodes. They are faster, more durable, and ideal for portable and field-based applications.

3. Wireless pH Sensors

The advancement of wireless technology has facilitated the deployment of pH sensors in remote or hazardous environments where wiring is impractical. These devices often come with Bluetooth or Wi-Fi capabilities for data logging and transmission.

4. Self-Cleaning and Maintenance-Free Sensors

Some modern pH sensors come equipped with self-cleaning systems, significantly reducing downtime and maintenance costs. This is especially useful in harsh environments like mining and chemical processing.

Challenges in pH Sensor Usage

Despite their wide application and technological improvements, pH sensors face several challenges:

- Drift and Calibration: Over time, sensor readings can drift due to electrode wear or contamination, necessitating regular calibration.

- Limited Lifespan: Traditional glass electrodes can be fragile and have a limited lifespan, especially in aggressive environments.

- Fouling and Clogging: In applications like wastewater treatment, pH sensors can become clogged with biological material, affecting accuracy.

- Environmental Factors: Temperature, pressure, and other environmental variables can influence sensor readings if not properly compensated.

Addressing these challenges has become a key focus for manufacturers, leading to the ongoing development of more durable and accurate pH measurement solutions.

Market Trends and Growth Opportunities

The global pH sensor market is poised for significant growth, driven by rising environmental concerns, stricter regulations, and the need for efficient process monitoring. According to Persistence Market Research, the demand for advanced analytical instrumentation, including pH sensors, is expected to rise across various sectors.

Key Market Drivers:

- Environmental Regulations: Stricter laws regarding industrial waste discharge are pushing organizations to invest in reliable pH monitoring solutions.

- Industrial Automation: The integration of pH sensors in automated systems is fueling demand across smart factories and plants.

- Growing Healthcare Needs: With the expansion of pharmaceutical and biotech sectors, precise analytical tools like pH sensors are becoming indispensable.

Regional Insights:

According to a study by Persistence Market Research, North America and Europe dominate the pH sensor market due to established industrial infrastructure and stringent regulatory frameworks. However, the Asia-Pacific region is witnessing rapid growth fueled by expanding manufacturing sectors and urban development.

Competitive Landscape:

The market features a mix of global players and niche technology providers. Companies are focusing on strategic partnerships, product innovations, and regional expansion to strengthen their market position. Based on analysis from Persistence Market Research, leading players are also investing in digital transformation initiatives to enhance product offerings.

Future Outlook

The future of pH sensors looks promising with advancements in AI-based diagnostics, miniaturization, and integration with cloud-based analytics platforms. As industries become more data-driven, real-time pH monitoring will be critical for operational efficiency and sustainability.

Additionally, companies that prioritize user-friendly design, reliability, and after-sales support will likely dominate the evolving market. Reports from Persistence Market Research indicate that there will be a growing shift toward fully integrated sensor platforms offering multifunctional capabilities such as conductivity, temperature, and ORP (oxidation-reduction potential) alongside pH measurement.

Conclusion

pH sensors are more than just instruments for measuring acidity or alkalinity — they are vital tools that ensure product quality, regulatory compliance, and process safety across industries. As environmental regulations tighten and industrial processes become increasingly automated, the demand for accurate, durable, and smart pH sensing solutions is expected to soar.

Insights from Persistence Market Research affirm that innovation, regional diversification, and smart technologies will be the driving forces shaping the future of the pH sensor industry. For businesses, investing in advanced pH sensing technology is not just a compliance measure — it’s a strategic step toward operational excellence and sustainability.