With the trend from Si IGBT to SiC MOSFET in electric vehicle (EV) power electronics, the junction temperature is expected to increase from 150°C to 175°C with the potential to exceed 200°C. This brings significant challenges for thermal management. Die-attach and substrate-attach materials play an important role in effective thermal management, and IDTechEx has noticed a transition from traditional solder alloys to Ag sintering among many leading automotive original equipment manufacturers (OEMs). IDTechEx’s report, “Thermal Management for EV Power Electronics 2024-2034: Forecasts, Technologies, Markets, and Trends”, summarizes the important developments of die-attach and substrate-attach technologies, as well as the commercial roadmap of these technologies.

Challenges of die-attach materials

Traditional die-attach and substrate-attach materials are solder alloys (eutectic and soft soldering), electrically conductive adhesives (ECA) based on polymers (typically silicone or acrylic), and many others. A typical EV power electronics or semiconductor package consists of various materials, each with different mechanical properties. From a long-term reliability viewpoint, the difference in the coefficient of thermal expansion (CTE) between adjacent materials, such as die, die-attach, and substrate, is one of the most limiting factors since it induces thermo-mechanical strains during power packaging manufacturing or under operational conditions, which lead to package wear-out. The thermo-mechanical strain may be associated with deformations and with resulting mechanical stresses during local or global temperature changes. Temperature changes are commonly encountered during device manufacturing or packaging, such as vapor depositions and soldering operations, and under working conditions, for instance, switching operations and global environmental temperature changes.

Rise of Ag sintering

Due to the increasing junction temperatures, several leading OEMs, including Tesla, VW, and BYD, have transitioned from solder alloys to Ag sintering technologies. Ag sintering offers numerous advantages, such as behaving like a bulk material and providing a high melting temperature. It also has a CTE similar to that of copper (17.5). The sintered porous Ag bondline delivers high thermal conductivity (200-300 W/mK) while maintaining a thin bondline (20-30 μm and occasionally even 10 μm). Consequently, this technology effectively reduces overall thermal resistance. However, Ag sintering also presents some challenges. One significant challenge is ensuring high shear strength. Early versions of Ag sintering performed optimally on Ag metallized surfaces, whereas many direct bound copper (DBC) substrates use Cu as the metallization layer. However, advancements in formulations and sintering procedures (e.g., in N2 environments) have enhanced compatibility with raw copper surfaces.

Sintering times are typically lengthy, even with the application of pressure. Recent improvements, such as the use of nano inks and dry film transfer techniques, have reduced sintering times to two to five minutes and shortened pre-drying times. These advancements also require only mild pressures (significantly less than 30 MPa), making them suitable for use with ultra-thin dies.

Despite the rising popularity of Ag sintering technology, IDTechEx learned from one of the leading semiconductor suppliers that it plans to stay with traditional solder alloys for some of its products rather than sintering. Considering the higher costs of Ag sintering compared with solder alloys, IDTechEx believes that Ag sintering will be used in mid- to high-end vehicles from leading automotive OEMs, whereas low-end vehicles will continue using traditional solders. The costs of Ag sintering could vary significantly depending on the suppliers, volume, customer relationship, and other factors. A supplier reported its material costs to be around US$2/g. More details on the costs are included in IDTechEx’s report, “Thermal Management for EV Power Electronics 2024-2034: Forecasts, Technologies, Markets, and Trends”.

Emerging Cu sintering

Much like Ag sintering, Cu sintering pastes come in different versions with pressured and pressure-less with different gaseous environments. There are pressure and pressure-less variants under N2 or H2. Cu sintering theoretically can mitigate the high-cost issues of Ag sintering, a leading supplier reported that Cu sintering costs as little as half that of Ag sintering.

As of 2024, IDTechEx has not seen any large-scale adoption of Cu sintering technologies in EV power electronics, as Cu sintering is a much more difficult process, largely due to copper oxidation reducing the effectiveness of the bond. While copper has the potential to offer lower costs in the long run, as it is currently in the early stage of development, the copper sintering pastes are at a similar or even higher cost than silver sintering pastes. However, there are already a few companies (e.g., VW) that are testing Cu sintering. Despite the vague timeline, IDTechEx believes that copper sintering might start to get adopted towards the end of 2024 or by early- to mid-2025.

Summary

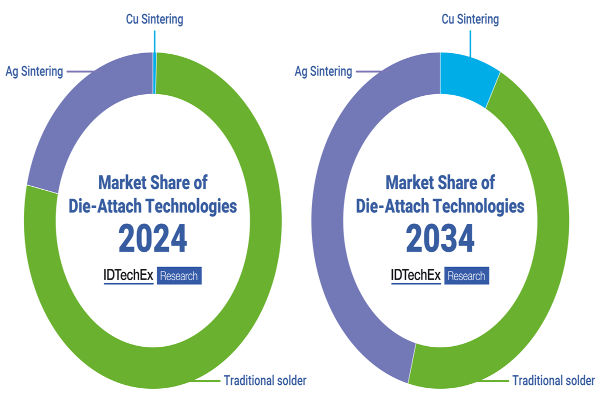

IDTechEx asserts that innovations in die-attach technologies are crucial for ensuring effective thermal management in EV power electronics. However, given the cost-sensitive nature of the automotive industry, the adoption rates of Ag and Cu sintering technologies are significantly influenced by their expense. As of 2024, leading automotive OEMs such as Tesla, Hyundai, VW, and BYD have already begun adopting Ag sintering. With advancements in Cu sintering technologies, IDTechEx has observed several pilot projects underway, suggesting that commercial adoption of Cu sintering could commence as soon as late 2024. By 2034, IDTechEx projects that Ag sintering will capture around half of the market, although traditional solder alloys will continue to have a presence.

It is also important to note that die-attach technologies are just one approach to enhancing cooling efficiency. Other solutions, such as double-sided cooling, will be employed in conjunction to improve overall performance. IDTechEx’s report on the topic, “Thermal Management for EV Power Electronics 2024-2034: Forecasts, Technologies, Markets, and Trends”, offers an in-depth technical analysis of various cooling methods and a 10-year market forecast for these technologies.