In the modern automotive world, sensors are essential for ensuring that vehicles operate efficiently and safely. One of the most critical types of sensors in today’s vehicles is the powertrain sensor. These sensors monitor various components within the vehicle’s powertrain to enhance performance, efficiency, and safety. But what exactly is a powertrain sensor, and how does it fit into the broader system of automotive sensors? This article will answer these questions and delve deeper into the role of powertrain sensors in engine management systems.

The automotive powertrain sensors market is projected to grow from US$ 18.47 billion in 2024 to US$ 30.77 billion by 2031, registering a CAGR of 7.6%. Key drivers include the rising demand for fuel-efficient and environmentally friendly vehicles, stringent emissions regulations, and advancements in sensor technology. Emerging applications of AI and ML are enhancing sensor capabilities, enabling predictive maintenance, adaptive control, and autonomous driving. The surge in Electric Vehicle (EV) production, with 14 million EVs sold globally in 2023, further boosts market growth. Asia Pacific is expected to hold a dominant share of 52% in 2024, driven by high automobile production in China, India, and Japan. Temperature sensors lead the market, accounting for 26% of the share, as they ensure optimal performance in EVs and internal combustion engine (ICE) vehicles. With ICE vehicles still dominating the market at 75%, powertrain sensors are essential for real-time data monitoring and fuel efficiency.

What is a Powertrain Sensor?

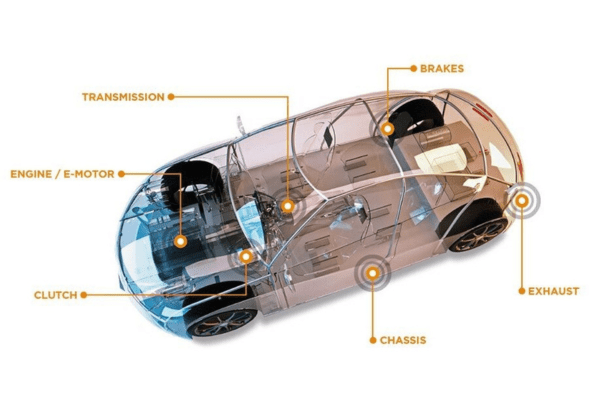

A powertrain sensor is a device used to monitor and measure various parameters within the powertrain system of a vehicle. The powertrain, which consists of components like the engine, transmission, driveshafts, and differential, is responsible for delivering power to the wheels. Sensors within this system ensure that all the components work in harmony, providing the optimal power output while maintaining efficiency and reducing emissions.

Powertrain sensors monitor crucial data such as engine speed, transmission fluid temperature, and the position of various engine components. This data is sent to the vehicle’s electronic control unit (ECU), which makes real-time adjustments to ensure smooth performance. Examples of powertrain sensors include the crankshaft position sensor, throttle position sensor, and transmission speed sensors. These sensors are critical in managing the power distribution, fuel efficiency, and overall drivability of the vehicle.

What is Powertrain in Automotive?

The powertrain in automotive terms refers to the collection of components that generate power and transmit it to the wheels. It is the central system that drives the vehicle, and it consists of several key parts:

- Engine: The heart of the powertrain, which burns fuel to create power.

- Transmission: This component transfers the engine’s power to the wheels, ensuring the correct speed and torque are applied.

- Differential: This allows the wheels to turn at different speeds, which is essential when turning corners.

- Driveshafts: These transfer the power from the engine to the wheels.

The role of the powertrain in automotive design is to provide a vehicle with the ability to accelerate, decelerate, and maintain speed, all while minimizing fuel consumption and emissions. Advanced powertrain systems include more components, like electric motors in hybrid or electric vehicles, but the core function remains the same: to provide efficient power delivery from the engine to the wheels.

What Are Automotive Sensors?

Automotive sensors are specialized devices embedded in various vehicle systems to monitor and collect data about the vehicle’s performance and environment. These sensors are critical for modern vehicles because they enable the electronic control units (ECUs) to make adjustments that optimize vehicle operations. From monitoring engine health to detecting external factors like tire pressure, sensors ensure that the vehicle runs smoothly, safely, and efficiently.

There are numerous sensors throughout a vehicle, each serving a specific function. These sensors can be broadly categorized into two groups: active and passive. Active sensors send out a signal or wave, then measure how that signal is affected by the vehicle’s components, while passive sensors only measure changes in the environment. Automotive sensors work together to control engine performance, braking systems, airbag systems, lighting, and much more.

Key automotive sensors include:

- Oxygen Sensors: Help control the fuel-air mixture for combustion.

- Temperature Sensors: Monitor engine, transmission, and cabin temperatures.

- Pressure Sensors: Keep track of oil, fuel, and tire pressure.

- Speed Sensors: Measure wheel and vehicle speed to aid in anti-lock braking and stability control systems.

- Position Sensors: Determine the location of engine components like the throttle or camshaft.

These sensors are essential for maintaining vehicle safety, fuel efficiency, and performance.

What Are the 5 Sensors in the Engine Management System?

The engine management system (EMS) is a critical part of modern vehicles, and it relies on several sensors to monitor and control various engine parameters. Among the many sensors used in the EMS, five play particularly crucial roles in ensuring that the engine operates efficiently:

- Crankshaft Position Sensor: This sensor monitors the position and speed of the crankshaft, which helps the engine control unit (ECU) determine when to fire the fuel injectors and ignition system. It is essential for maintaining proper timing and ensuring smooth engine operation.

- Camshaft Position Sensor: Similar to the crankshaft sensor, the camshaft position sensor tracks the position of the camshaft to optimize the timing of the engine’s valves. This sensor is key to ensuring proper air-fuel mixture and engine efficiency.

- Mass Airflow Sensor: This sensor measures the amount of air entering the engine, providing the ECU with crucial data for adjusting the air-fuel mixture. Proper airflow is essential for combustion and engine performance.

- Oxygen Sensor: Oxygen sensors are located in the exhaust system and monitor the level of oxygen in the exhaust gases. They help adjust the air-fuel ratio to ensure complete combustion, minimizing emissions and improving fuel economy.

- Throttle Position Sensor: This sensor monitors the position of the throttle valve, which controls the amount of air entering the engine. By monitoring the throttle position, the sensor allows the ECU to adjust the fuel injection rate for smooth acceleration and consistent engine performance.

These five sensors are fundamental in managing the engine’s performance, emissions, and fuel efficiency. They work in tandem with the ECU to ensure the engine operates under optimal conditions and adjusts to changing driving circumstances, whether it’s accelerating, cruising, or idling.

The Role of Powertrain Sensors in Optimizing Automotive Performance

The integration of powertrain sensors with the engine management system and other vehicle systems highlights their importance in modern automotive technology. By continuously monitoring critical engine parameters, powertrain sensors allow for the precise control of various engine functions. This leads to smoother performance, better fuel efficiency, reduced emissions, and longer engine life.

For instance, powertrain sensors help regulate the engine’s combustion process, ensuring that the fuel is burned efficiently. They also provide data on the transmission’s shifting patterns, optimizing the timing of gear changes to enhance driving comfort and fuel efficiency. As the automotive industry moves toward more advanced powertrains, especially in electric and hybrid vehicles, the role of powertrain sensors will continue to evolve. New sensors will be developed to monitor electric motors, battery charging, and regenerative braking systems.

The Future of Powertrain and Automotive Sensors

As vehicles continue to evolve, the role of powertrain and other automotive sensors will only grow in importance. With the rise of electric vehicles (EVs) and hybrid technologies, sensors are becoming increasingly sophisticated to manage new systems like battery management and electric motor performance. Additionally, the growing use of autonomous vehicles will require even more sensors to detect and respond to road conditions, obstacles, and traffic situations.

The automotive industry is also seeing the development of advanced driver assistance systems (ADAS), which rely heavily on sensors to ensure safety features like lane departure warnings, automatic braking, and adaptive cruise control. Powertrain sensors will continue to play a crucial role in these systems by ensuring that the vehicle’s powertrain works seamlessly with other vehicle components to enhance both safety and performance.

Conclusion

Powertrain sensors are integral to modern vehicle performance, playing a vital role in everything from fuel efficiency to emissions control and overall drivability. The five key sensors in the engine management system – crankshaft position, camshaft position, mass airflow, oxygen, and throttle position sensors – help manage and optimize the engine’s operation, ensuring that it runs smoothly and efficiently. As automotive technology continues to evolve, the role of powertrain and automotive sensors will only grow in significance, making them crucial to the future of the automotive industry.