ROHM has developed AI-equipped MCUs (AI MCUs) – ML63Q253x-NNNxx / ML63Q255x-NNNxx – that enable fault prediction and degradation forecasting using sensing data in a wide range of devices, including industrial equipment such as motors. These MCUs are the industry’s first to independently execute both learning and inference without relying on a network connection.

As the need for efficient operation of equipment and machinery continues to grow, early failure detection and enhanced maintenance efficiency have become key challenges. Equipment manufacturers are seeking solutions that allow real-time monitoring of operational status while avoiding the drawbacks of network latency and security risks. Standard AI processing models, however, typically depend on network connectivity and high-performance CPUs, which can be costly and difficult to install.

In response, ROHM has developed groundbreaking AI MCUs that enable standalone AI learning and inference directly on the device. These network-independent solutions support early anomaly detection before equipment failure – contributing to a more stable, efficient system operation by reducing maintenance costs and the risk of line stoppages.

The new products adopt a simple 3-layer neural network algorithm to implement ROHM’s proprietary on-device AI solution “Solist-AI.” This enables the MCUs to perform learning and inference independently, without the need for cloud or network connectivity.

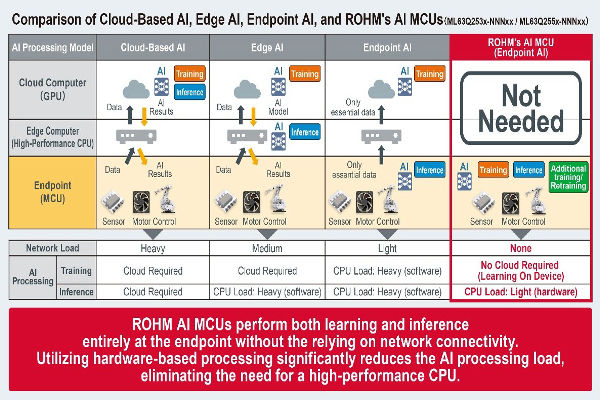

AI processing models are generally classified into three types: cloud-based, edge, and endpoint AI. Cloud-based AI performs both training and inference in the cloud, while edge AI utilizes a combination of cloud and on-site systems - such as factory equipment and PLCs - connected via a network. Typical endpoint AI conducts training in the cloud and performs inference on local devices, so network connection is still required. Furthermore, these models typically perform inference via software, necessitating the use of GPUs or high-performance CPUs.

In contrast, ROHM’s AI MCUs, although categorized as endpoint AI, can independently carry out both learning and inference through on-device learning, allowing for flexible adaptation to different installation environments and unit-to-unit variations, even within the same equipment model. Equipped with ROHM’s proprietary AI accelerator “AxlCORE-ODL,” these MCUs deliver approximately 1,000 times faster AI processing compared to ROHM’s conventional software-based MCUs (theoretical value at 12MHz operation), enabling real-time detection and numerical output of anomalies that “deviate from the norm”. In addition, high-speed learning (on-site) at the point of installation is possible, making them ideal for retrofitting into existing equipment.

These AI MCUs feature a 32-bit Arm Cortex-M0+ core, CAN FD controller, 3-phase motor control PWM, and dual A/D converters, achieving a low power consumption of approximately 40mW. As such, they are ideally suited for fault prediction and anomaly detection in industrial equipment, residential facilities, and home appliances.

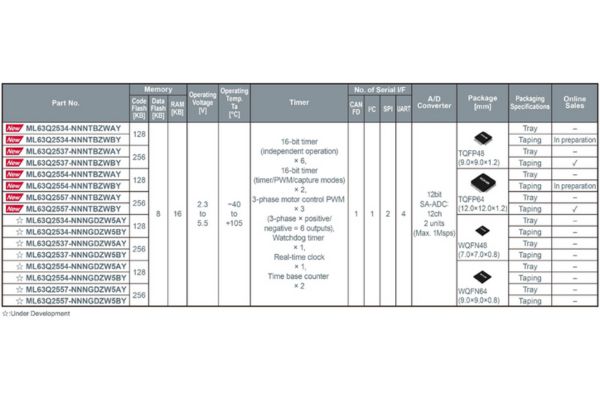

The lineup will consist of 16 products in different memory sizes, package types, pin counts, and packaging specifications.Mass production of 8 models in the TQFP package began sequentially in February 2025. Among these, two models with 256KB of Code Flash memory and taping packaging are available for purchase, along with an MCU evaluation board, through online distributors.

ROHM has released an AI simulation tool (Solist-AI Sim) on its website that allows users to evaluate the effectiveness of learning and inference prior to deploying the AI MCU. The data generated by this tool can also serve as training data for the actual AI MCU, supporting pre-implementation validation and improving inference accuracy.

To facilitate adoption, ROHM has built an ecosystem in collaboration with partner companies, offering comprehensive support for model development and integration. Going forward, ROHM will continue to expand this ecosystem, providing more user-friendly environments by assisting with training data creation and proposing optimal implementation methods.

About Solist-AI (Solution with On-device Learning IC for STandalone-AI)

Solist-AI is ROHM’s on-device AI solution designed for edge computing applications. Drawing inspiration from the musical term “Solist (Soloist)”, which signifies solo performance, this innovative solution enables real-time learning and inference directly on standalone edge devices without relying on cloud servers. Powered by ROHM’s proprietary on-device learning AI technology, Solist-AI is characterized by its compact design and low power consumption, contributing to the expansion of sustainable AI innovation.

・ Solist-AI is a trademark or registered trademark of ROHM Co., Ltd.

Product Lineup

These AI MCUs integrate a 32-bit Arm Cortex-M0+ core (Maximum operating frequency: 48MHz) and ROHM’s proprietary AI accelerator AxlCORE-ODL that performs learning and inference using a 3-layer neural network. On top, leveraging versatile timer functions such as 3-phase motor control PWM along with a wide range of serial interfaces like CAN FD and 12-bit A/D converter enables flexible support for control and data processing in industrial equipment, residential facilities, and home appliances.

AI MCU Development Support Tools

ROHM AI MCUs utilize a standard Arm core, ensuring compatibility with commercially available tools as well as ROHM’s proprietary integrated development environment. To evaluate learning and inference, an AI operation verification simulator is provided, along with a real-time viewer for assessing AI effectiveness.